What Is The Working Principle Of Rexroth Vane Pump

Rexroth vane pump working principle: When the vane rotor rotates, the tip blade is close to the inner surface of the stator. The working volume of the two blades and the inner surface of the rotor and stator consists of small to large oil absorption and then large to small oil drainage. When the blade rotates for a circle, one oil absorption and oil drainage process finished.

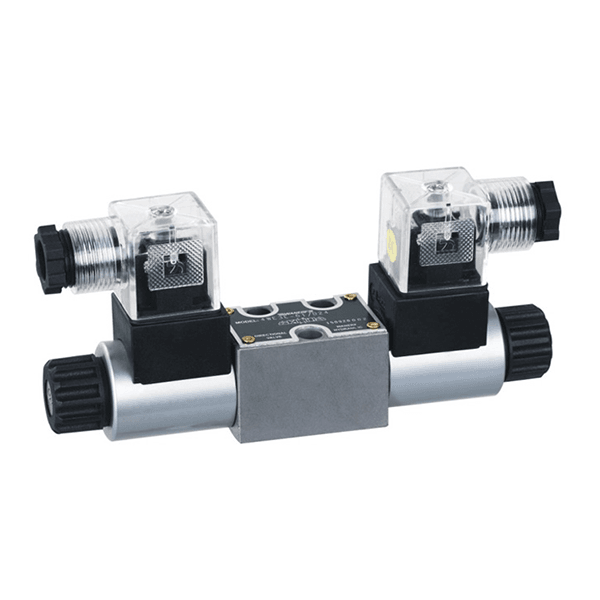

Rexroth vane pump

a. The working principle of single Rexroth vane pump.

Rexroth Rotor Pump contains stator, blade , oil distribution pan and end cap. The inner surface of the stator is a cylindrical hole. There is eccentricity between rotor and stator. The blade can slide flexibly in the slot of the rotor. When the rotor rotates, with the centrifugal pressure and pressure oil entering the blade root, the top of the Rexroth blade is close to the inner surface of the stator. So a sealed working chamber is formed between the two adjacent blades, the oil distribution plate, the stator and the rotor.

When the rotor rotates counter-clockwise, the blade on the right side of the diagram extends outward. And the volume of the sealing chamber increases gradually, resulting in a vacuum. Therefore, the oil is sucked through the upper windows of the suction port 6 and the oil distribution plate 5. And on the left side of the graph. Rexroth blade retracts inward which makes the volume of the sealing chamber reduced. Then the oil in the sealing chamber extrudes through another window of the oil distribution pan and the pressure port 1 and exported to the system. This kind of pump is single vane pump. Because it sucks oil and presses oil once in the process of rotor rotation.

The rotor is subjected to radial hydraulic unbalanced pressure, so it is also unbalanced pump. Its bearing load is large. When changing the eccentricity between stator and rotor, the displacement of the pump can be different. So this kind of pump is also variable displacement pump.

b. The working principle of double vane pump.

The stator surface contains two long radius arcs, two short radius arcs and four transition curves. And the stator and rotor are of the same center. When the rotors rotate clockwise, the volume of the sealing chamber increases gradually at the upper left and the lower right. That is the oil absorption area. The volume of the sealing chamber decreases gradually at the lower-left and the upper right. That is the oil pressure area.

There is a sealing area between the oil suction area and the oil pressure area to separate them. The rotor of this pump rotates one circle, and each sealed working chamber completes oil suction and oil pressure twice, so it is double vane pump. The two Oil-absorbing area and two Oil pressing area of the pump are radially symmetrical, and the Hydraulic pressure on the rotor is radially balanced. So they are also balanced vane pumps. The instantaneous flow rate of double vane pump is pulsating, and the pulsation rate is small when the number of Blades is 4 times. For this reason, the number of blades of double vane pump is generally 12 or 16.

Leave A Comment